- Home

- About Us

Implement the strategy of aluminum saving copper

Implement the strategy of aluminum saving copper

Realize industrial service to the country - Products

ProductsCopper Aluminum Composite SeriesCopper Clad Aluminum Busbar Copper Clad Aluminum Rod Copper Clad Aliminum Flat Wire Copper Aluminum Composite Round WireCopper Clad Aluminum Wire Series

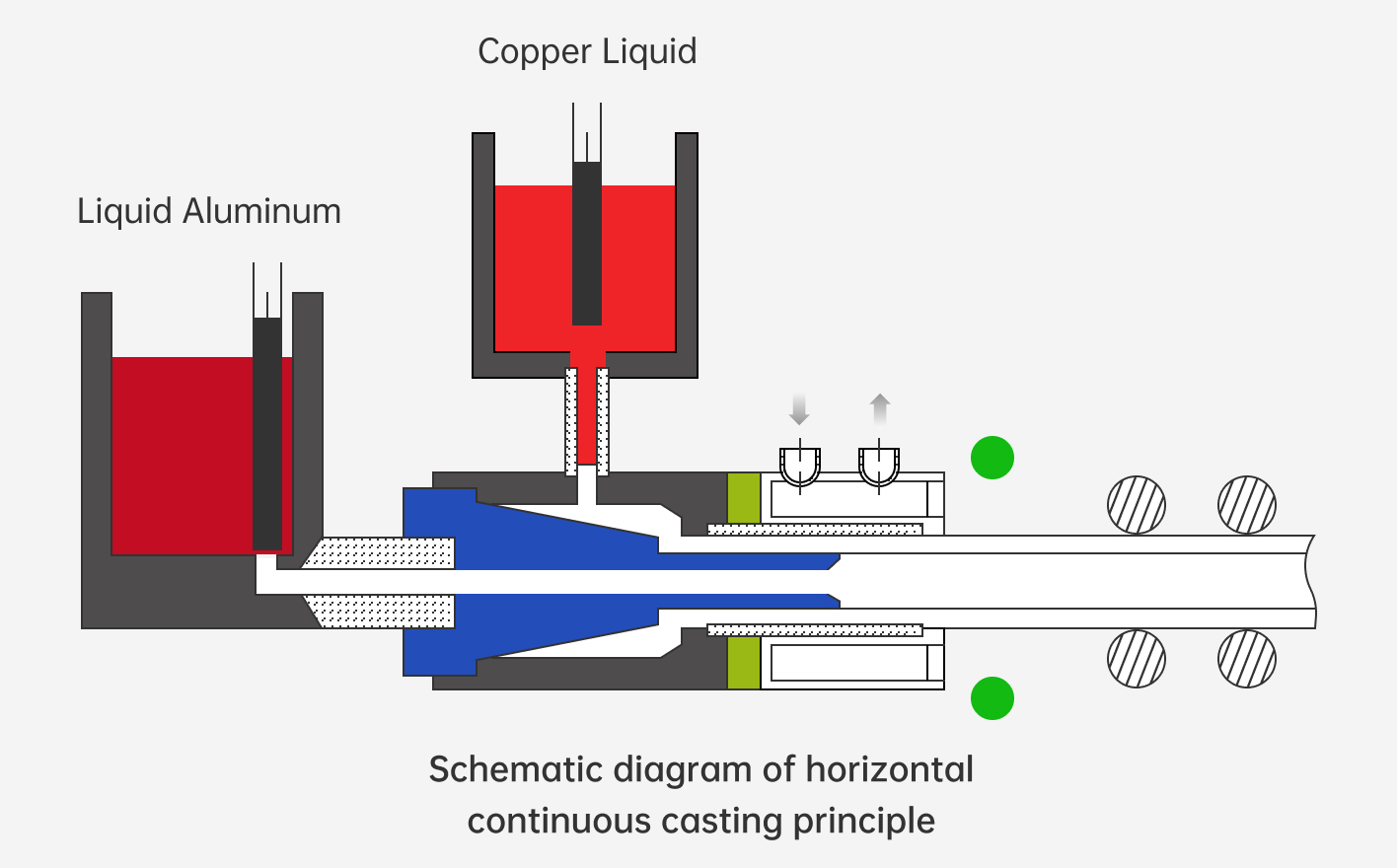

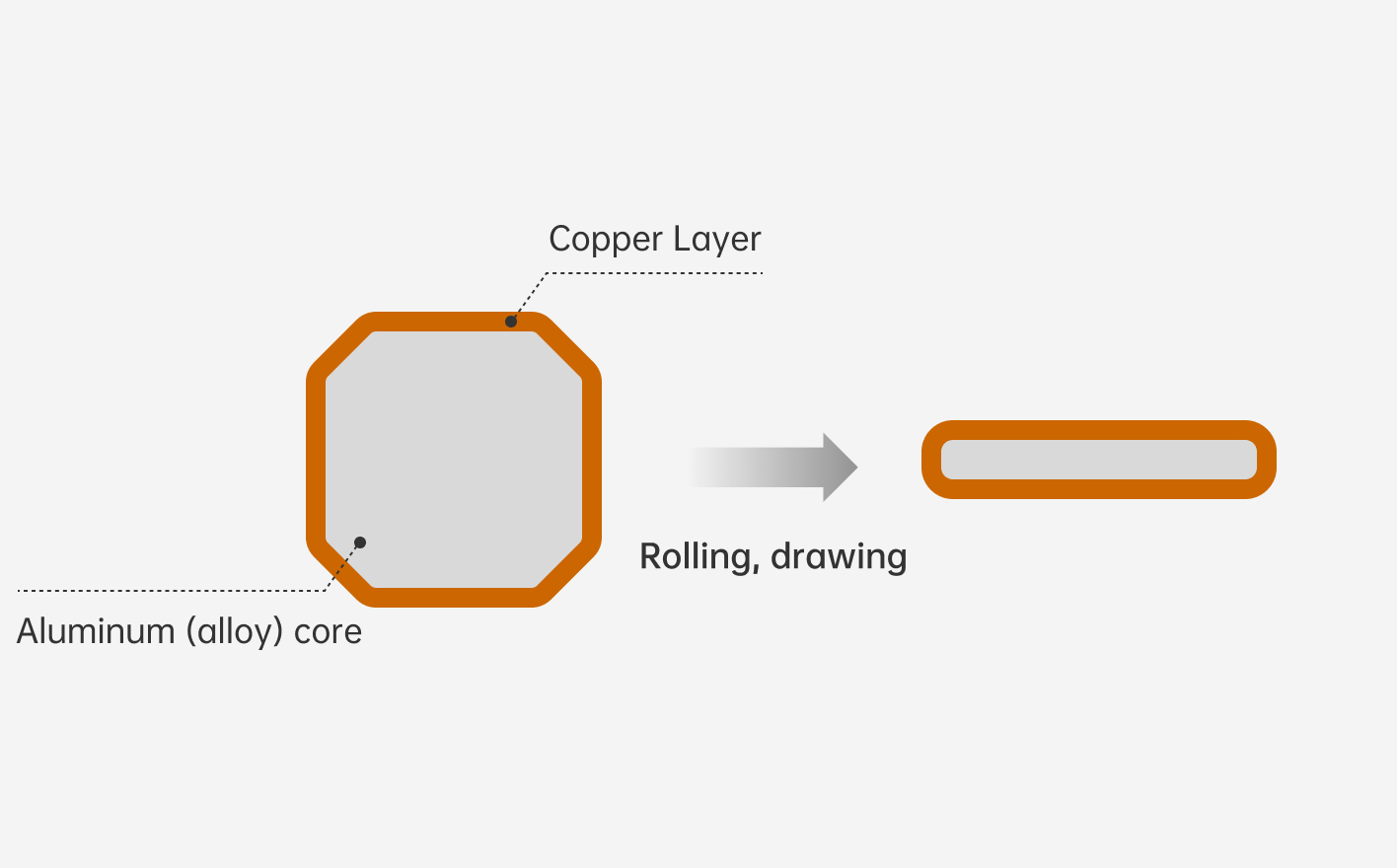

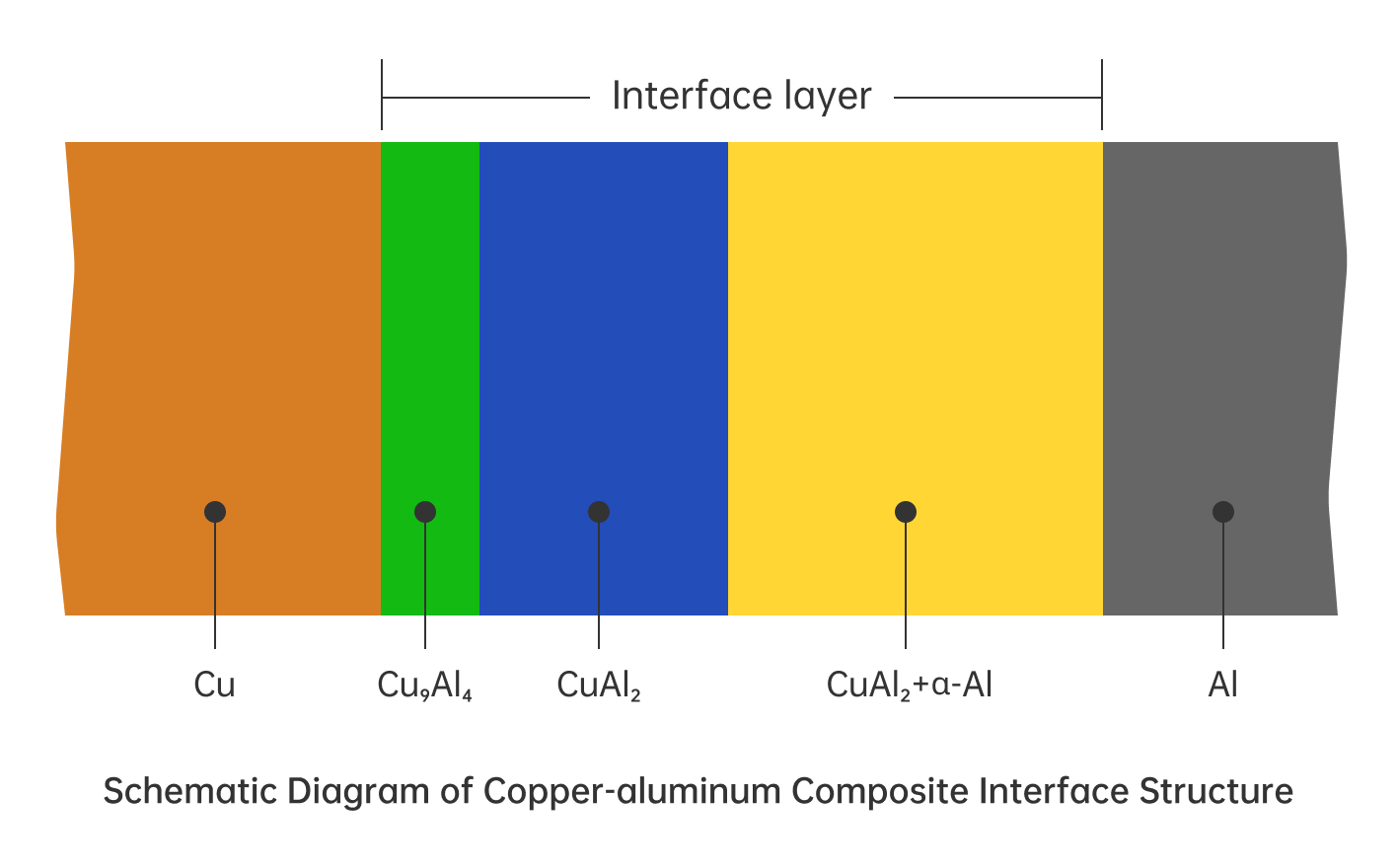

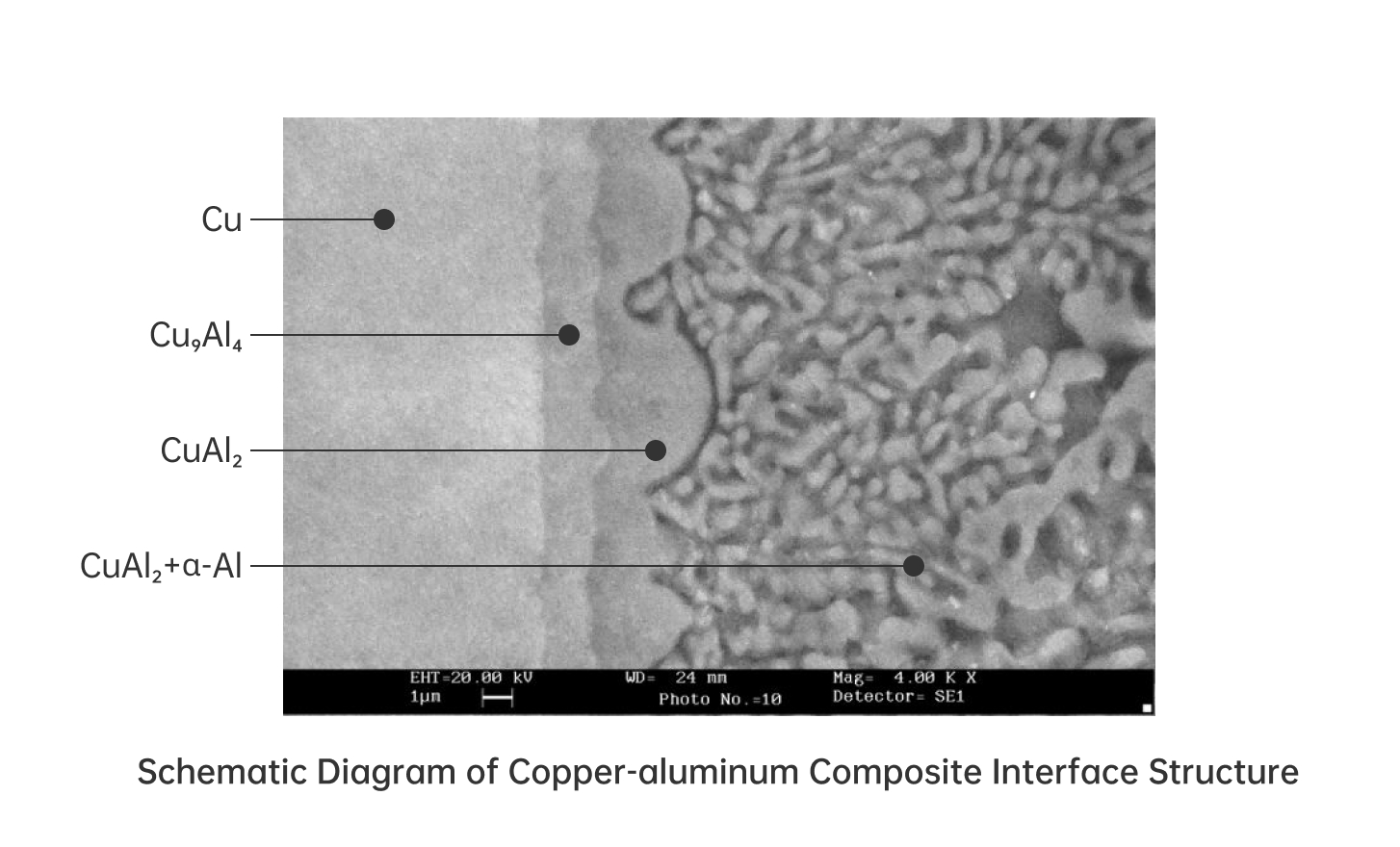

Committed to the development and manufacture

Committed to the development and manufacture

of copper and aluminum composite materials - Technology &Specification

Technology &Specification

Provide solutions of new Copper Clad Aluminum Busbar

Provide solutions of new Copper Clad Aluminum Busbar

conductor materials for global customers - Application

For customers in the global electrical industry

For customers in the global electrical industry

Cost reduction and lightweight composite solutions

- Contact Us

If you have any product needs or suggestions

If you have any product needs or suggestions

Please contact us